Clean Energy + Transition

"Flexible, Stable, Cost-effective and Efficient Energy”

We aim to be a leading investor, owner and operator of distributed generation, clean energy, and energy transition assets in Southeast Asia. Our business portfolio and focus comprises a diverse technology base of co-generation and waste heat recovery plants, via distributed generation, district and centralized

cooling systems and energy storage.

We utilize our fully integrated operating platform and in-house expertise to build & maintain facilities, organically add value and efficiently integrate new assets, realizing cost synergies in the process. Our business is underpinned by stable cash flows, with the majority of our power contracted under long-term, inflation-linked contracts.

Distributed Generation

Our commitment to continuous improvement in everything we do drives us to develop innovative, industry leading solutions to complex problems from

power and steam to cooling.

Our Co-generation or Combined Heat and Power (CHP) is the simultaneous production of electricity with the recovery and utilisation heat for steam. Whereas our Tri-generation Energy Systems or Combined Cooling, Heat and Power (CCHP) refers to the simultaneous generation of electrical power, chilled water and hot water. We look into large scale projects for industrial parks as the sole energy operator to dedicated plants for large scale industrial businesses from glove makers to food & beverage operators. These generation plants tend to reduce your overall energy cost while delivering sustainable energy.

Co-generation Energy Systems

Tri-generation Energy Systems

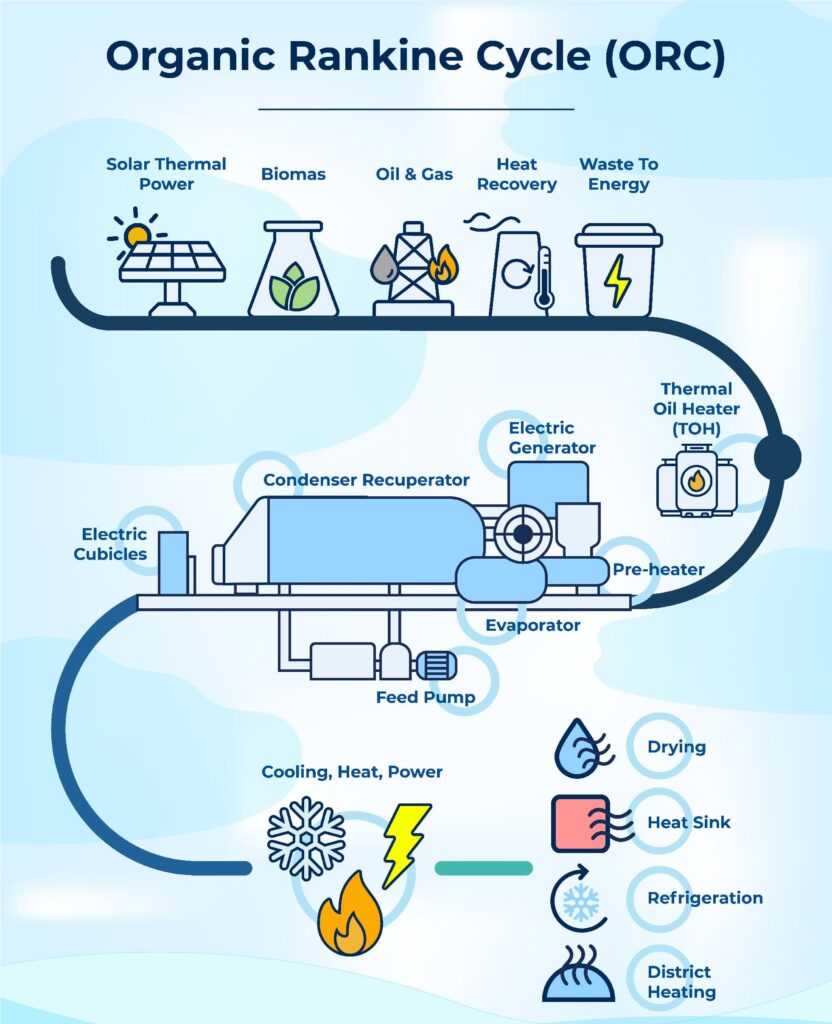

Waste Heat Recovery

For large scale heavy industries that are energy guzzlers such as cement, steel and glass, much heat is released via their processes which allows us to capture it and convert into green electricity. These heat recovery plants not only reduce your energy cost but significantly minimizes environmental impact due to Co2 pollution. We aim to be a leading player in this sector supporting businesses around the region with our core technology partners.

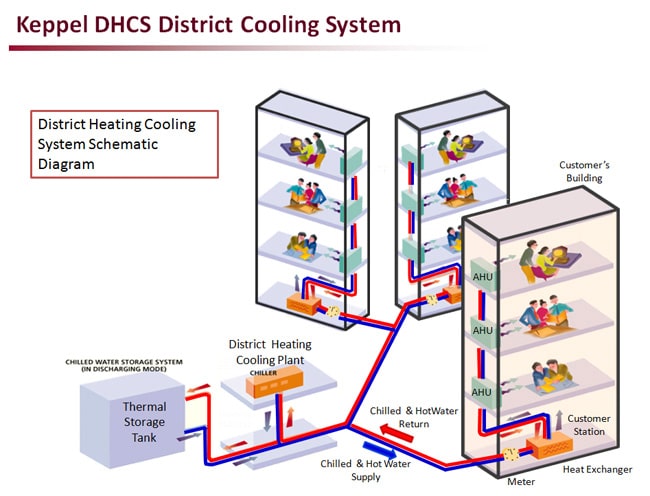

District and Centralized Cooling

Our integrated cooling business ranges from district cooling plants to centralized cooling systems and increasing efficiency by implementing many technologies such as nano liquids to improving operational efficiency. Our portfolio of cooling assets provide customers fixed cooling rates and temperatures with improved efficiency while allowing to focus on their core business.

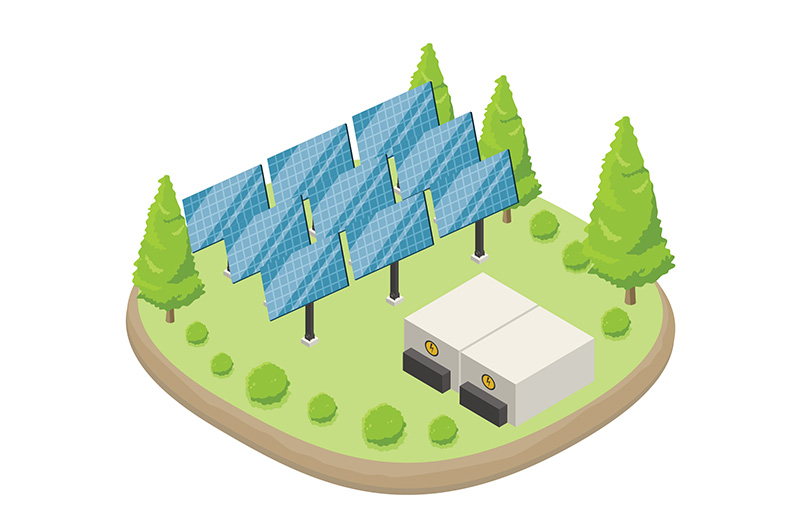

Energy Storage

Our batteries store power generated by our facilities when the sun is shining, then dispatch the stored power to the grid or a customer’s relevant premises to supplement dips in operation – such as when clouds roll in and temporarily reduce the sunlight reaching a solar plant’s panels. The stored power during off-peak hours can also be dispatched during periods of peak customer electricity demand. We are looking at growing our integrated energy storage portfolio in line with supporting our generation assets and customers’ peak demand.

“We create sustainable economic advantages for our customers and shareholders and actively working on improving environmental conditions aimed in reducing fuel consumption and prevent CO2 emissions”

Gopala Krishnan C.P Gopalan

Director, Group Strategy & Policy

Sustainable, Reliable & Affordable Energy!